1.4 Plate heat exchangers

Plate heat exchangers are devices, the heat exchange surface is formed by a set of thin plates stamped with a corrugated surface. The working medium in the heat exchanger gap move in complicated form channels between adjacent plates in countercurrent. The channels for the heating and the heated heat transfer are alternated with each other. The corrugated surface of the plates increases the turbulence in fluid flow and heat transfer coefficient increases.

Classification of devices plate heat exchangers

They are divided on the degree of accessibility of the heat transfer surface for mechanical cleaning and inspection at:

- demountable - are very flexible in the design of settings, allowing to increase or decrease the heat transfer area by the addition or subtraction of the plates. Easily assembled and disassembled for cleaning or repair;

- semidemountable (semiwelded) heat exchangers - a part of this design can be assembled using spacers and to be collapsible, and some - by welding; They used very rarely;

- collapsible (welded, soldered) heat exchangers. It compares favorably with collapsible to withstand higher pressures and temperatures. But at the same time, if you change the mode of operation and the need to change the thermal power, will have to completely replace the device. Moreover, their repair is also associated with certain difficulties: the construction will have to remove completely and take to the service department, which entails a long process easy.

The most widely used gasketed plate heat exchangers, where the plates are separated from one another by spacers. Mounting and dismounting of these devices is carried out quickly enough, clean heat transfer surfaces requires minor labor costs. Plate heat exchangers semidemountable mutually welded, and access to the heat exchange surface is only possible by the progress of one of the working media. Plate heat exchangers are welded in non-separable units connected to the pads in the overall package.

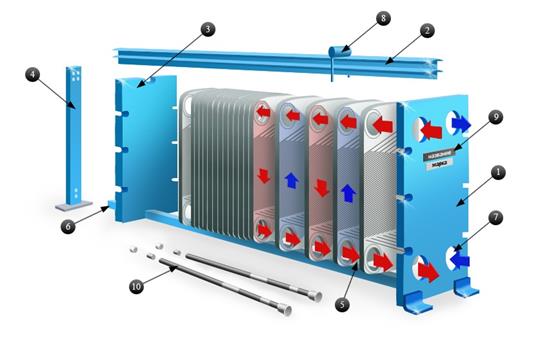

Key design elements of gasketed plate heat exchangers (Figure 1.29). Corrugated thin plates. They may be made of steel, titanium and other alloys, depending on the design requirements. Due to the relief surface, they provide high turbulence of the medium flow and thus a high heat transfer coefficient. It is important to understand in order to maximize the performance of equipment, it is necessary to make a correct calculation of plate heat exchanger, which will strike a balance between the flow rate, the volume of the working environment, and dimensions of the unit.

1 – front fixed plate, 2 – upper guide, 3 – rear sliding plate, 4 – rear stand (tripod), 5 – working plate with seal, 6 – lower track 7 – nozzles, 8 – rollers to move the plates along the guide, 9 – schild with the name and technical data, 10 – pin

Figure 1.29 – Gasketed plate heat exchanger.

Two carrier beams. The heat exchanger plates are fixed on the upper beam and lower supports.

The mobile and fixed base plates. Between them the design of beams and plates (fixing is carried out by tightening the bolts) are placed.

Seals. They are attached between the plates, channels responsible for sealing and prevent mixing environments.), Exchanger gaskets can be made of nitrile rubber (for oily media), of EPDM (for high temperatures) or Heat Seal material (unique development Alfa Laval used in steam environments).

The design of a gasketed plate heat exchanger. Brazed models are made in the same way, only the connection plates are made by soldering without the use of gaskets. Therefore, these models are cheaper demountable, but are more expensive to maintain and are suitable only in high-pressure environments (about 50 bar).

Design features.

The front and rear stationary sliding plate - represent a unit frame and pull together the working plate.

Guides - are fixed on the front plate and the rear rack-rack, serve as a support for the movable plate and the plates (the latter are moved along the rails on special rollers).

The plates have four openings and form the two channel isolated and sealed - for cold and hot working fluid.

Rubber seals are fixed in the grooves of the plates using epoxy glue or clips. Glue is not recommended for use in systems with large pressure drops, and the clip - in an oxidizing atmosphere and at a part of the "autopsy" of equipment.

Gasketed plate heat exchangers

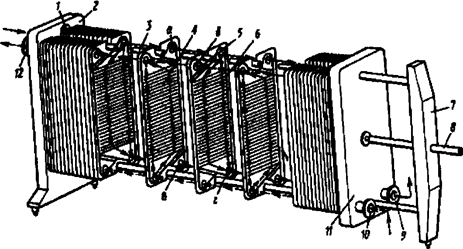

Gasketed plate heat exchangers are manufactured in three versions, including a cantilever frame on the two-reference frame, on the three-bearing frame. Gasketed plate heat exchanger on the two support frame (shown in Figure 1.30). The apparatus consists of a number of heat transfer plates 4 placed on the top and bottom ends of the horizontal bars 3. The bars are fixed to the fixed plate 2 and front plate 7. The pressure screw 11 and the plate 8 are compressed to form the heat exchange section.

The plates have four through-holes (a, b, c, d) that form two separate channels from each other system. To seal the plates and channels are rubber gaskets Gasket 6 is laid in the groove and the contour plate includes two holes in the plate through which the inflow and output occur in coolant channel between adjacent plates, and the gasket 5 sealed two other holes in the plate. To enter the coolant and the apparatus are output nozzle 1, 9, 10, 12 located on the fixed and movable plates.

1, 9, 10 and 12 – nozzle; 2 – fixed plate; 3 – rod; 4 – heat exchanger plate; 5 and 6 – gasket; 7 – stand; 8 – the screw; 11 – pressure plate a, b, c and d – passages.

Figure 1.30 – Gasketed plate heat exchanger on the two-base frame

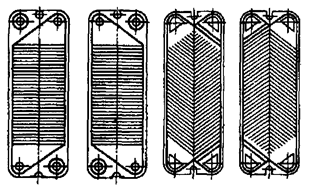

The plates vary in their location of holes for heat transfer in the plate with a diagonal arrangement of the holes. And they both perform left and right. Due to the alternation of two separate systems of channels are formed in the package left and right plates (Figure 1.31).

Figure 1.31 – Plates with a diagonal (a) unilateral and (b) the location of holes

Plate with interchangeable one-sided arrangement of holes. When assembling the right of the plate obtained by rotating them relative to the left by 180 °. The left and right plates differ in the arrangement diagonal arrangement pads and are thus not interchangeable, also considered the heat transfer plates in the apparatus using the boundary plate mounted on the ends of the packages. Commercially available plate heat complement plates stamped from sheet metal thickness of 1 mm. The corrugations of plates typically have a cross-sectional profile of an equilateral triangle height 4 ... 7 mm, and a base length 14 ... 30 mm (for viscous fluids up to 75 mm). The corrugations perform horizontal, "herringbone", at an angle to the horizontal plates and other material. Galvanized or corrosion-resistant steel, titanium, aluminum, nickel silver.

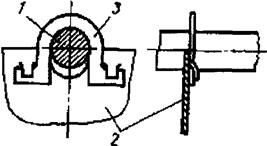

The gasketed plate heat exchangers 2 normally fixed bracket 3 on the upper bar 1 (Figure 3.32). Lower rod does not carry the load from the weight plates and serves only to fix them in position. Such fastening plates makes it easy to remove them from the package or inserted into it without removing the movable plate and the other plate.

1 – top bar; 2 –the plate; 3 – bracket

Figure 1.32 – Assembly mounting plate on the top bar.

Gasket plate heat exchangers are made of rubber molded and strengthened in the groove of the plate with glue. Racks and pressure plate heat exchangers are made of carbon steel thickness of 8 ... 12 mm. The disadvantages of plate heat exchangers is the impossibility of their use at a pressure of more than 1.6 MPa.

One of the major advantages of plate heat exchangers to other types of heat exchangers is the possibility of various schemes of packet layout plates. Packet in this case is called a group of plates, forming a system of parallel channels in which the coolant moves in only one direction (from top to bottom or vice versa). The package is substantially similar to one in the course of multi-pass pipes for shell and tube heat exchangers. For a given coolant flow increase in the number of packets increases the coolant velocity, which intensifies the heat transfer and increases the flow resistance. Combining plate inside the heat exchanger manufacturers achieve optimum heat transfer options for each type of device. The main condition in this case the flow of coolant in the heat exchanger should be turbulent (indignant). The only way to achieve high efficiency and self-cleaning plates. Since the coolant flow in heat exchangers such as pipe in pipe - Laminar, quiet, hence the low heat transfer coefficient and large size classic shell and tube heat exchangers.

Circuit arrangement the plate heat exchanger.

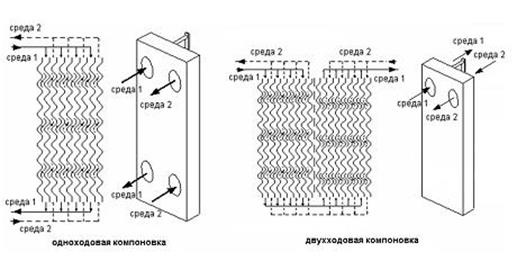

Today, major manufacturers of plate heat exchangers offer the following arrangement principle (Figure 1.33):

- Straight-arrangement of the heat exchanger when the coolant is immediately divided into parallel flows through all the channels and plates, merging into a single channel, enters the port for output fluid;

Figure 1.33 – Scheme layout of the plate heat exchanger

- Multiport layout of the heat exchanger. In this case, a more complex circuit, the coolant circulates through the same number of channels, making a U-turn at the plate. This is achieved by setting the dividing plates that include partitioning deaf. Maintain, clean disassemble and assemble a heat exchanger is much more difficult.

Plate heat exchanger plates arranged one behind the other rotated by 180 degrees. This principle of the heat exchanger circuit layout creates a package with four collectors for drainage and supply of liquids. The first and the last plate, respectively, are not involved in heat exchange, the back plate blank without ports.

Multidirectional plate heat exchanger is used in cases where it is necessary to achieve the small temperature difference between the heat carriers. This heat exchanger tubes are arranged on both the front and the fixed end on the pressure plate. In a multi-pass plate heat exchanger flows change direction in one or more strokes. This may cause the following phenomena.

Advantages of plate heat exchangers:

1) Plate heat exchangers are compact (4–8 times smaller in overall dimensions equal in size shell and tube heat exchangers, heat transfer surface);

2) Plate heat exchangers provide a high heat transfer coefficient of 3000-4000 W/(m2·K) (more than 3 times higher than in the shell and tube) due to high heat transfer rate in the channels (3.1 m/s) at a relatively for such low speeds hydraulic resistance;

3) Gasketed plate heat exchangers are suitable for maintenance, cleaning and repair;

4) The possibility of different layouts plate that allows you to choose the optimal mode for the given coolant flow.

Disadvantages of plate heat exchangers:

1) Inpossibility to work at high pressures due to insufficient sealing gaskets have gasketed plate heat exchangers, the risk of deformation of plates welded at (collapsible heat exchangers operate at pressures up to 1 MPa, welded – up to 4 MPa);

2) The problem of maintenance of welded plate heat exchangers – cleaning and repairs difficult.