1.5 Submersible vehicles

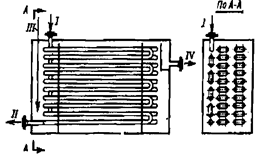

A specific feature of this type of vehicles is the availability of capacity-box, in which the heat exchange tubes are immersed. In the box is a cooling medium such as water. Devices of this type are used as condensers, coolers or refrigerators. There are coiled and sectional sets. The principal device is a single-threaded immersion condenser-cooler shown in Figure 1.34. The heat exchange surface comprises tubes connected by welding or flanges; transition from one pipe to another is realized with the help of twins. The cooled stream passes successively pipe disposed in the horizontal row, and then passes into the pipes of the next row, and so on.

I – a pair of oil; II – cooled petroleum product; III – cold water; IV – heated water

Figure 1.34 – Scheme of single-threaded immersion coil condenser-cooler

When high flow rate of the cooling flow to reduce flow resistance applied refrigerators coiled collector in which the cooled stream with a special header is divided into several parallel streams. Less flow resistance of the collector unit as compared to single ended is achieved by reducing the flow rate and path length.

In case of using such a device as a condenser, the refrigerator where, because of the partial or total condensation of the flow volume decreases rapidly, can be applied submersible collecting apparatus with a variable number of flows. At the beginning of the device, where the pair move mainly whose amount is significant, the number of concurrent streams may be higher than in the part of the apparatus where the complete condensation of the vapors and cooling the condensate occurs. Such a device is useful for increasing the thermal effect device, since maintaining the original number of flow paths around condensate speed in the final part of the apparatus may be small, and therefore, the heat transfer coefficient in that part of the apparatus will be low. It should be borne in mind that the wrong choice of the place of reducing the number of threads on the way condensing environment may lead to increased hydraulic resistance, as it was the case in some existing installations.

The disadvantages of this type of devices is their bulkiness and increased metal consumption. In addition, the box free passage section for water is large, whereby the water flow rate is small and relatively small coefficients of heat transfer from the coil to the water walls.