1.9 The main methods of heat transfer enhancement

Apply the following basic ways of intensification of heat transfer:

- Design rough surfaces and complex shapes that promote turbulence in the boundary layer flow;

- The use of turbulence-inserts in the channels;

- An increase in the surface area of heat transfer through the fins;

- The impact on the electric charge flow, ultrasonic and magnetic fields;

- Turbulence in the boundary layer pulsations organization of the oncoming flow velocity and spin;

- Mechanical effect on the heat transfer surface by means of its rotation and vibration;

- Granular application nozzle as a stationary and a pseudo mobile state;

- Adding to the coolant solids or gas bubbles.

Methods need to improve the efficiency of heat transfer

Methods of increasing efficiency may be divided into:

а) production (or production);

- b) design.

By manufacturing include:

- High chemical water treatment;

- Conduct prompt washing of heat exchanger;

- The use of a heat exchanger in accordance with the design parameters.

By design include:

- Changes in the geometric surface heat exchanger at the production stage;

- Replacement of the heat exchange surface in the existing equipment to another (if possible).

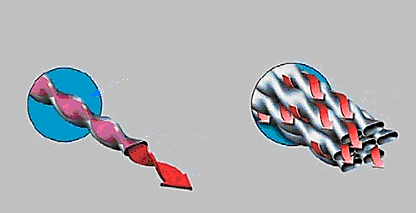

For example, the technology of twisted tubes (Twisted tube) (Figure 1.40) of the company «Koch Heat Transfer» allows you to create standard equipment on the basis of shell and tube heat exchangers with characteristics much better than the standard. Tubes of the tube bundle are twisted in a special apparatus, which allows to create a swirling flow in the heat exchanger tubes and attach to each other through every inch. This increases the number of tubes compared to the conventional shell and tube heat exchanger 40 % at the same size housing and eliminate mechanical vibration.

Figure 1.40 – The tube bundle with twisted pipes

Benefits apprat heat exchangers with twisted tubes over conventional:

- Improved thermodynamic characteristics;

- The organization of counter- heat-exchange environments;

- Low pressure loss;

- Pollution reduction and improved cleanability;

- The elimination of vibration;

- The absence of diaphragms.