2.1 Classification of furnaces

There are different constructions of tube furnaces, which are characterized by the method of the heat transfer, by a quantity and by the form of furnace cameras, with the number of sections (cameras) in the zone of radiation, by the alignment of the axes of torch and pipes, by the ignition method of fuel, by the type of the irradiation of pipes, with the number of flows of the heating product, by the arrangement of convection camera relatively radiant, by the length radiant and convection pipes.

The fundamental characteristics of tube furnaces are the productivity of furnace, useful thermal load, the calorific intensity, the heating surface and the efficiency of furnace.

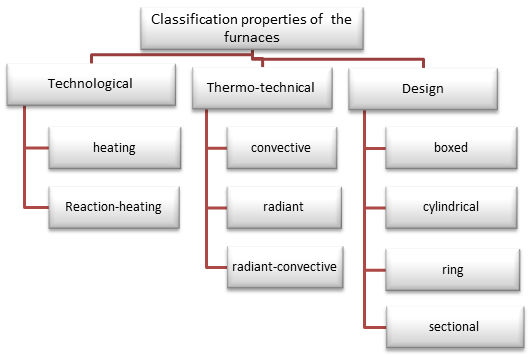

According to the degree of importance Main and natural bases for the classification of furnaces in the logical sequence are the following signs (Figure 2.1).

Figure 2.1 – Classification of the furnaces

Technological signs.

By the technological designation distinguish furnaces heating and reaction - heating.

Reheating furnaces are intended for the heating and the partial or total evaporation of raw material. They include the furnaces installations of the distillation of oil and petroleum residue, stabilization of oil, of catalytic cracking, the reforming, coking, catalytic dehydrogenation and polymerization (with the extension reaction chambers) and others.

The heating – reaction furnaces are intended for heating of raw material and communication to it of the heat, necessary for conducting the endothermal reactions. They include the furnaces of the installations of the thermal cracking, pyrolysis, the tubular reactors of dehydrogenation;

Using the ignition method of fuel the tube furnaces are subdivided into three basic types:

- with the torch combustion of fuel;

- with the radiating walls of furnace;

- with the flat flame.

Thermo-technical signs

Using the method of the transfer of heat from the fuel combustion products to the flow the processed raw material tube furnaces are divided into:

- convective;

- radiant;

- it is radiant- convective.

In the convective furnaces to 80 % a total quantity of heat it is transferred due to the convection, and a remaining quantity of heat is transferred by radiation. In furnaces of this type are provided with milder conditions of heat exchange (smaller temperature difference between the tube wall and a processed product). In the radiant-convection furnaces type 40 ... 60 % of the amount of heat transferred by radiation, and the rest - convection. The major amount of radiant heat furnaces transmitted radiation. Camera convection here is of secondary importance.

Design features.

The shape of the frame:

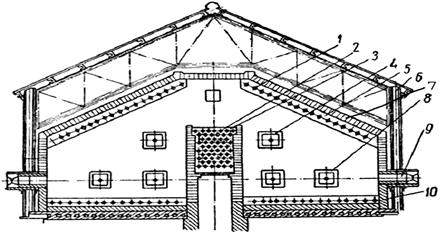

- a) The box-wide shaped cameras, narrowly shaped cameras (flat or sloping arch) (Figure 2);

- b) cylinder;

- c) ring;

- d) sectional.

Figure 2.2 – The box-shaped frame

The configuration of the furnace and the relative position of the cameras determine placement of pipe screens in radiant furnace chamber.

Pipes shielded vault, side, front and saddle walls and floor of the furnace. There are single and double row screens. The figure shows a furnace with a box shape frame.

According to the number of radiation chambers:

- a) single-chamber;

- b) two-chambers;

- c) the multi-chamber.

According to the location of pipe coil (Figure 2.3):

- a) horizontal;

- b) vertical.

According to the location of burners:

- a) side;

- b) the hearth.

According to the fuel system:

- a) a liquid fuel (F);

- b) a gaseous fuel (F);

- c) liquid and gaseous fuels (F + G).

|

a) the horizontal position of the pipe coil |

b) the vertical position of the pipe coil |

Figure 2.3 –Location of the pipe coil

By way of fuel combustion:

- a) torch;

- b) flameless combustion.

According to the location of the chimney:

- a) is a tubular furnace;

- b) on the convection chamber (Figure 4).

In the direction of movement of flue gases:

- a) gas riser;

- b) downflow gas;

- c) a horizontal flow of gases.

Downstream flue gas stream decreases the likelihood of stagnant zones, so providing for more efficient heat transfer.

Figure 2.4 – Location of the chimney above the convection chamber