2.4 Convection furnaces

Convection furnace is one of the oldest types of furnaces. They are a kind of transition from the refinery plant to the furnaces of radiation-convective type.

Nowadays this type of furnaces is not used, as compared to furnace radiation or radiation-convective they require more costs for their construction and during operation too. The only exceptions are special cases where it is necessary to heat the temperature sensitive substance is cold in comparison to flue gases.

The furnace consists of two main parts - the combustion chamber and the tubular space which are separated from each other by the wall, so that the pipes are not directly subjected to the flame, and most of the heat is transferred by convection to the heated substance.

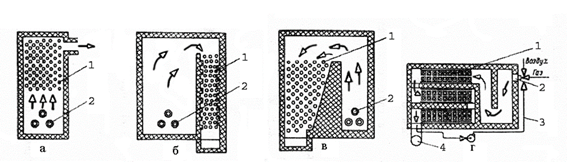

Figure 3.72 shows the convection type furnace with an upper (Figure 2.32, a) and bottom (Figure 2.32, b, c, d) tap of flue gas. The horizontal arrangement of the coil (Figure 2.32, a, b and c) makes it relatively easy to remove the product from the pipe and blow them at planned shut-down for repairs, emergency, etc. The vertical arrangement of the coil allows much easier to fix and repair the pipe. In order to reduce the convective coil burnout pipe separated from the furnace by the wall (Figure 2.32, b, c, d). Decreasing along the flue gas cross section of the convective motion camera provides more uniform calorific heating surface for different rows of pipes.

Burnout of pipes can be reduced with decreasing in temperature of flue gas entering the convection chamber or combustion of fuel with a large excess of air. However, these measures dramatically worsen furnace showings.

|

a, b, c) with horizontal tubes (cross-section) |

d) a furnace with a vertical pipe (the plan) |

1 – the tube bundle; 2 – nozzle; 3 – a conduit for recirculation of the combustion gases in the furnace; 4 – chimney

Figure 2.32 – Convection ovens