2.5 Radiative-convective furnace type

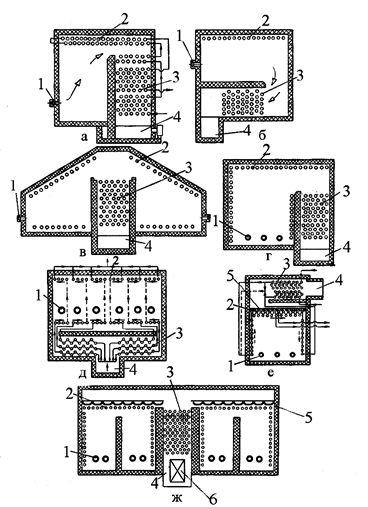

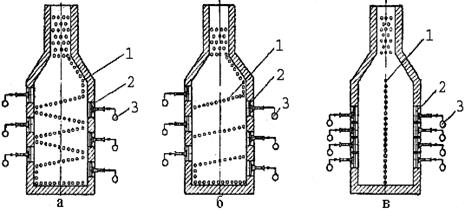

Radiative-convective type of furnaces are widely used. Figure 2.33 shows the radiative – convective furnaces with the bottom tap of flue gases and horizontal arrangement of pipes.

The furnace shown in Figure 2.33 (a) and it is used as a reactive-heating. Upper ceiling wall is distichous. The second raw of tubes is used as a reaction zone.

For reduction the flue gas temperature before the convection coil provides flue gas recirculation, which are particularly removed from the flue by exhauster.

The ceiling of heating furnaces, bottom and side screens typically implemented single-row (except the double exposure of the screen). Constructive feature of the furnace below 2.33 (b) is the existence of a horizontal wall that separates radiation camera from the convective.

The two-chambered furnace with an inclined arch (Figure 2.33, c) and single-row ceiling and bottom screens has a common convection chamber. Assignment of inclined arch is the alignment of thermal loads ceiling screen. The furnace used for processing two products with different heating modes or two independently controlled flows at the same time. Single-chamber furnaces are built with single inclined arch at low powers.

In Figure 2.33 (d) performed six-branched tube furnace with bottom location of the convection chamber. Combustion products pass through the single row, raised from the furnace bottom screen and ramify on two opposite sides enter the convective tube bundle. Bottom screen supports are attached to the grids of the convective beam.

1 – nozzle; 2 – radiant tube; 3 – convective tube; 4 – chimney; 5 – arch; 6 – air heater

Figure 2.33 – Radiative-convective furnaces with horizontal tubes adapted to run on liquid and gaseous fuels (cross-sections)

The furnace shown in Figure 2.33 (e) combustion products pass through the ceiling double-row screen and enter the convection tube bundle disposed in the upper part of the furnace. On the top row of ceiling pipes laid with gaps shaped refractory bricks, promoting a better washing of the gases of the second row of tubes. The furnace is designed to heat one or two product streams.

In furnaces (Figure 2.33, a, b, c) injector axis is perpendicular to the axis of the radiant tubes. The furnaces (Figure 2.33, d, e, f, g) axis parallel pipes and nozzles, which leads to an undesirable uneven distribution of thermal stress along the length of the tubes.

Four-chambered furnace (figure 2.33, g) is used for heating two or more heated streams. The combustion products pass through a single-row ceiling screen where laid profiled fireproof brick with clearances.

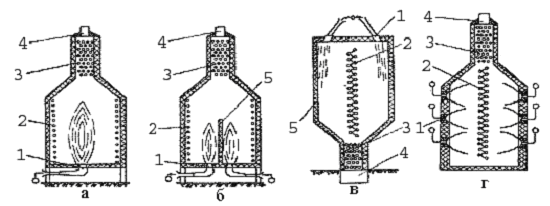

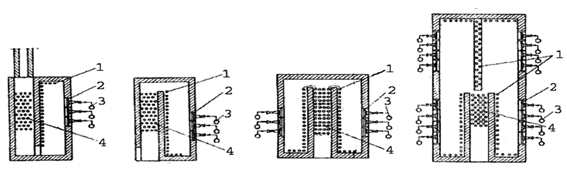

Figure 2.34 (a, b) shows narrow-chambered furnace with a vertical axis of the flambeau. These furnaces run on gas or combined gas-liquid fuels, since the location of the nozzles for the liquid fuel in the middle of the hearth would complicate their maintenance. Upper location of chamber arrangement reduces the resistance of the gas flue, reducing the height of the chimney up to 10 ... 20 m. Draft is performed by one or more tubes mounted above the convection chamber at a distance of 3 ... 6 m from each other. Furthermore, the location of the upper convection chamber provides smooth without twists natural (upward) movement of the products of combustion.

The distinctive design feature of the furnace in Figure 2.34 (b) is the presence of the separation wall 5. When burning fuel of the torch is laid on the separation wall, which begins to radiate heat. This furnace volume and by flat torch.

Furnaces illustrated in Figure 2.34 (c, d) have double-row, double-screen exposure and lower (Figure 2.34, c) or top position of the convection chamber 5. After combustion of fuel the part of flambeau planks on the separation wall, which starts to emit the heat. This is furnace with volume – grazing flambeau.

1 – gas burners; 2 – radiant tubes; 3 – convection tube; 4 – gas output from the furnace; 5 – the separation wall

Figure 2.34 – Radiative-convective type of furnaces with horizontal tubes

Illustrated in Figure 2.34 (c, d) furnaces have double-row double-sided radiation screen and a lower (Figure 2.34, c) or top position of the convection chamber. Axles of furnace burners (Figure 2.34, c) are disposed at an angle whereby the flame is laid on a portion of the furnace side wall, beginning radiate the heat. This is furnace with grazing flambeau.

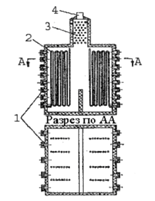

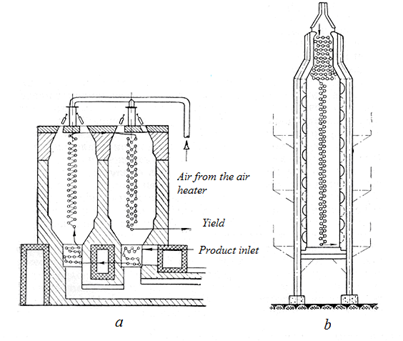

The furnace shown in Figure 2.35 has a vertical arrangement of coil of pipes and single-row double-screen heating. There are eight rows of four pipes on the each side of the furnace. The distance between rows is 3 m. between every two rows of tubes across the height of the furnace, as well as between the outermost rows of tubes and walls of end caps mounted nozzles on the 800 ... 1000 mm between each other.

1 – nozzle; 2 – pipe coil; 3 – convection tube; 4 – output; 3 – convection pipe bundle; 4 – chimney

Figure 2.35 – Radiative – convective type of furnace with single-row double-screen heating and vertical arrangement of pipes.

The need for high-rise structures for repair of pipes increases the specific consumption of metal (metal consumption per unit of heat output of the furnace).

Figure 2.36 shows a schematic diagram of vertical furnaces with radiant panel walls of flameless burner type. Radiant walls of pipes near the screen are situated at a distance of 0.6 ... 1.0 m. The minimum distance is determined by the necessary of a pass for the inspection and repair of pipes and ceramic burners. The panel burners gas fuel combustion occurs as a result of the panel is heated and becomes a source of radiation.

The combustion gases coming from the burners pass through the tube screen and enter the convective beam. Heat transfer in the radiation chamber happens by radiation from the hot gas and the walls, as well as the convection of gases.

In the furnaces with double-row screen heating can be carried out simultaneous heating of four products, but with an increase in the number of threads for more than two is difficult to ensure compliance with the permissible and actual calorific.

|

a) oven with overhead convection beam |

b) furnace with bottom location of the convective beam |

c) two lower furnace convective beams |

d) the furnace with additional side shields |

1 – pipe coil; 2 – radiating wall; 3 – gas manifold

Figure 2.36 – Furnaces with double screen double-sided heating and horizontal arrangement of pipes

The furnace illustrated in 2.36 (c) has two convection chamber which reduces the influence of the convection heat transfer from the gases to the screen.

Radiating wall furnace (Figure 2.36, d) comprised of alternating rows of burners and conventional masonry approximately the same height as the height of the burner. In addition to the central pipe of the screen double-row heating furnace through each row of burners at a laying-mounted side-row screens. They receive less heat radiation than the screen center, but this is offset by heat transfer from the gases as they pass to convective beam. The rest of the furnace does not differ from the furnace (Figure 2.36, a). Thermal indicators are considered by the uniformity of heating furnace tubes and their length equal to the circumference of the furnaces (Figure 2.36, a), but they are inferior in heat transfer capability for fine adjustment of the tube screen.

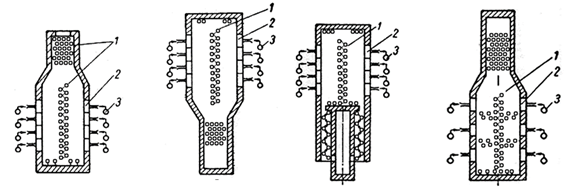

The furnace shown in Figure 2.37 (a) has a single-row zigzag horizontal screen. Radiant walls are composed of alternating rows of burners and masonry. The height of each row of masonry – 500 ... 600 mm, approximately equal to or slightly higher than the height of the burner.

1 – pipe coil; 2 – radiating wall; 3 – gas fuel manifold

Figure 2.37 – Furnaces with single-row double-screen heating and horizontal arrangement of pipes

The furnace shown in Figure 2.37 (a) gives the furnace show in Figure 2.36 (a, b, c, d) the possibility of fine adjustment of the heat transfer on the tube screen. When single-threaded movement of the heating pipes all radiant coil connected only tube counterparts. At the two-stream movement of the product by n rows of tubes have to (n - 1) with angled connections doubles.

Furnace (Figure 2.37, b) has a several single row screens situated parallel to each other at an angle of 13 ° to the horizontal. The value of the selected angle of inclination corresponding to the maximum coefficient of heat uniformity on the circumference of the pipe. Between tube screens installed one row of burners, alternating with masonry collected on hanging brackets. The distance between the radiating walls is 2.4 m. It corresponds to the maximum value of the coefficient of uniformity of heating the circumference of the pipe.

In furnaces of this type of adjustment thermal stress on the tube screen by varying the heat output of the corresponding series of burners. However, it is more difficult to carry out fine adjustment of heat transfer in the furnace than shown in Figure 2.36 (a, b, d).

Furnace (Figure 2.37, c) differs from the furnace at (Figure 2.36) by the fact there is double-row screen bilateral heating instead of single-row screen.

Figure 2.38 shows a single-row furnace wall screen with side or central location convective beam. Furnace (Figure 2.38, a) in the radiation chamber gases moving downwards, and in convective - upwards. Chimney installed in the upper part of the convection furnace tube bundle. In ovens (Figure 2.38, b) a natural gas stream in the radiant chamber, from the bottom up, rather than by a furnace in Figure 2.38(a).

|

a) oven with side convection chamber and the descending gas flow in the radiant chamber |

b) with lateral furnace chamber and convective upward flow of gas in the radiant chamber |

c) furnace with convection chamber which centrally located and has ascending gas flow in the radiant chamber |

d) furnace bunk with a central location convection chamber |

1 – pipe coil; 2 – radiating wall of the burners; 3 – gas manifold; 4 – convective chamber

Figure 2.38 – Furnaces with single-row wall-mounted screen horizontal arrangement of pipes

The furnace shown in Figure 2.39, is composed of two sections, and differs from other types of furnaces vertically arranged tubes.

.jpg)

1 – pipe coil; 2 – radiating wall; 3 –chimney

Figure 2.39 – The furnace with double screen bilateral heating pipes and vertical arrangement (plan)

Chimney is located between the sections, and directly connected to the convection chamber. For a more uniform heating of the convective chimney connection pipes and chambers are carried out along the entire height of the tube. One section of the furnace is different from the design of the furnace on (Figure 2.36, d) a vertical arrangement of pipes.

In the vertical furnace shown in Figure 2.40 (a) applying of bilateral irradiation of the screen is combined with the principe of grazing flame. Furnaces of this type can be a single-chambered or multi-chambered. The nozzles are typically located under the arch of the furnace, and the convection chamber is taken out downwards.

Figure 2.40 – Vertical furnace with bilateral irradiation screen

A variety of furnaces with bilateral irradiation screen is a vertical oven with gas burners, flameless combustion, made from special varieties of ceramics, catalyzing the combustion process. The furnace is a narrow chamber with a screen of bilateral irradiation, in the side walls of which there are a large number of ceramic nozzles (Figure 2.40, b). Such design of furnace makes it flexible, as it allows to adjust within broad limits thermal stresses both in height and length screens.

Cylindrical vertical tube furnaces are of serpentine tubes arranged vertically in one or two rows at the inner wall surface. Convective camera located at the top and it can be a finned tube (coefficient of fins is 3,2 ... 3,5). In such furnaces used a combined gas-oil fuel.