2.7 Standard Tube Furnaces

a) Narrow-chambered tube furnaces with upper flue gas, horizontal tubes in the radiation and convection chambers.

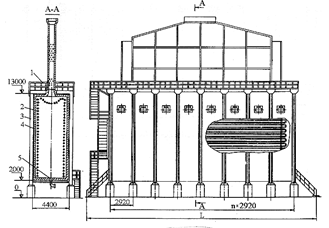

Narrow-chambered tube furnace with a single-row wall screens and free vertical flambeau with upper flue gas, horizontal tubes in the radiation and convection chambers.

The burners are arranged in one row in the hearth unit.

Changing the burner heat output almost doesn’t change the nature of diagrams summarizing the results of the heat flows in the tube screen.

The service of burners performs from one side of the furnace, whereby on a common foundation can be installed next to the two single-chamber furnace connected entryway and thus form as it were a two-chamber furnace.

There are seven sizes of furnaces lining of large-block lightweight heat-resistant concrete.

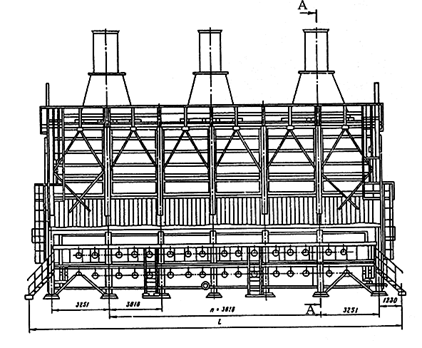

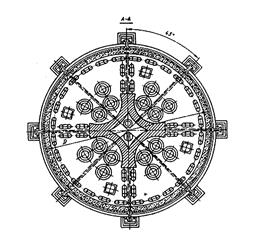

General view of the furnace and anchor bolts layout plan shown in Figure 2.42.

1 – a ladder platform; 2 – pipe coil; 3 – carcass; 4 – lining; 5 – burner

Figure 2.42 – Tubular single – chambered furnace with single-row screens and free vertical flambeau.

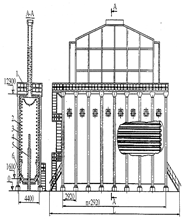

Two-chambered furnace with a single row wall screens and space by flat-torch with a top flue gases and the horizontal tube wall screens, box-shaped, with a horizontal pipe coil in two radiant cells, body-grazing combined fuel combustion.

The burners are arranged in a single row on each front wall at an angle of 45º. In the middle of the oven is installed wall separating the furnace into two identical cameras, which lay tilted combined fuel torches.

When changing the burner heat output almost unchanged nature of diagrams summarizing the results of the heat flows in the tube screen.

Service burners of the furnace - on both sides.

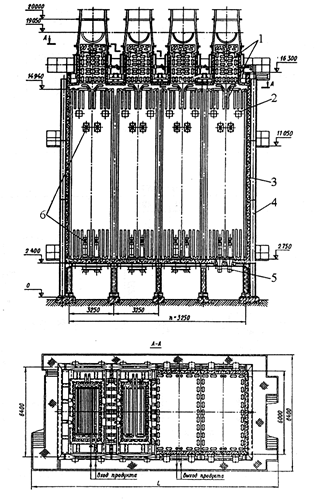

General view of the furnace shown in Figure 2.43.

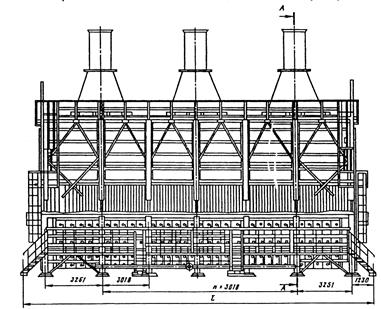

Double-chambered furnace with radiant panel walls of flameless burners with a central double-row tube screen, with the upper flue gas (type A2B2).

Burners are located in the frontal walls of the radiation chamber in five rows in the each wall forming two opposing radiating unit. Between the radiating walls installed pipe screen bilateral irradiation. Pipe screen can be two-lane, single-row, single and double row with variable pitch.

In order to ensure the independent regulation of heat output for the burners of each series having its own gas reservoir and hence, heat transfer area corresponding radiant coil.

1 – a ladder platform; 2 – pipe coil; 3 – carcass; 4 – lining; 5 – grazing wall; 6 – burner

Figure 2.43 – Tubular double chamber furnace with a single row wall screens and space by flat-torch.

Depending on the length of the radiation chamber pipes, having two versions (with a clutch of suspended refractory brick lining of heat-resistant lightweight concrete), the furnace is made of five sizes.

Furnaces of this type provide for flameless combustion of pure sweet gas, so harmful emissions are not available, that allows you to install chimneys with the highest mark of 25 m.

General view of the furnace, furnace incision and foundation bolts plan of arrangement are shown in Figures 2.44, 2.45.

Figure 2.44 – Tubular dual-chambered furnace with radiant panel walls of flameless burners with a central double-row tube screen.

1 – lining; 2 – carcass; 3 – pipe coil; 4 – exhaust and a viewing window; 5 – flameless gas burner; 6 – a ladder platform

Figure 2.45 –Tubular double chamber furnace with radiant panel walls of flameless burners with a central double-row tube screen (section A-A)

Two-chambered furnace with grazing fan-burning fuel gas with a central double-row tube screen, with the upper flue gas (type A2B2).

Construction of furnaces A2B2 and A2B2 are similar and they differ only in the radiating walls. The A2B2 type furnaces radiating wall of flameless burners replaced fan-burners arranged in two tiers on the front walls of the chamber and forming a radiation emitting two opposing blocks.

Pipe screen can be two-lane, single and double row with variable pitch. Changing the heating capacity of the two rows of burners can be changed Diagrams summarizing the results of the heat flows in the pipe coil.

The distinguishing feature is the fact that they can work in the fuel gas of variable composition.

General view of the furnace shown in Figures 2.46.

Figure 2.46 – Tube furnace type A2B2

b) Sectional box-shaped tube furnaces with free vertical torch.

Furnace – narrow-chambered, box-shaped with vertical arrangement of tube coil, free vertical-flaring combustion of combined fuel.

Dual fuel burners types GMG and HP are set in the hearth of the furnace. The vertical pipe radial coil placed along all four sides of the radiation chamber. On the walls of the radiation chamber located single-row wall screens, and between the radiation chamber - double row displays two-sided lighting.

There are four typical sizes of furnaces, each size is different number of identical radiation chambers. Above each chamber radiation is its convection chamber with horizontal smooth tubes. When operating on liquid fuel in these furnaces use of studded tubes unacceptable.

Each convection camera has its own convection gas collector and a control slide valve.

Service of burners performs on both sides.

Furnaces are lined with lightweight refractory concrete.

General view of the furnace and anchor bolts layout plan shown in Figure 2.47.

1 – coils; 2 and 6 – the exhaust, and a viewing window; 3 – lining; 4 – carcass; 5 – burner

Figure 2.47 – Tubular furnace VS type

Sectional furnace has rectangular and horizontal coiled coil, a free-standing and built-in convection chamber air heater, a free vertical flare combustion of fuel.

Pipe coils of each section consist of two or three transportable prefabrication packages. Each coil section is self-bearing, mounted directly on the hearth unit.

The walls of the furnace are assembled from light frames. DCB type burners arranged in the furnace hearth in one row by four burners in each section.

The furnace is equipped with radiant and convection coils. Radiation chamber may have from one to four sections.

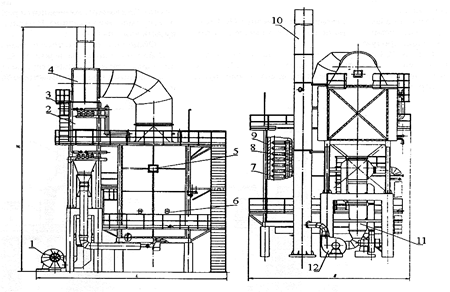

The general view of the furnace shown in Figure 2.48.

1– fan; 2 – convection chamber; 3 – a ladder platform; 4 – flue pipe; 5 and 6 – the exhaust, and a viewing window; 7 – radiant heating coil; 8 – grid plate; 9 – carcass; 10 – chimney; 11 – air heater; 12 – flue exhaust

Figure 2.48 – Sectional furnace with rectangular and horizontal coiled coil, a free-standing and built-in convection chamber air heater, a free vertical flare combustion.

c) Cylindrical tube furnaces with the upper chamber convection, vertical screen pipes and horizontal pipe convection-free vertical flaring combined fuel.

Combined burner arranged in the furnace bottom. On the walls of the radiation chamber mounted single-row or double-row tube wall screens.

The combustion gases - through the chimney, mounted on the furnace, and gas collector.

There are two versions of these furnace: radiation (without convection chamber) and radiation-convective (with convection chamber).

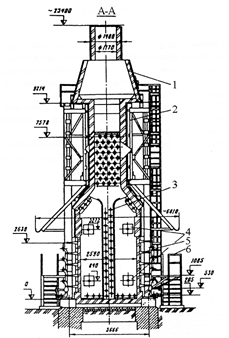

Four-cylinder furnace with a central prism in the furnace with grazing flambeau and the differential supply air plume height, single-row and double-row intersection wall screens, vertical arrangement of pipe screens in the four chambers of the radiation grazing of combined fuel combustion.

Combined burner arranged in the furnace bottom. Their axes inclined toward the reflector distributor installed in the center of the oven. The reflector is made in the form of a pyramid with concave faces, representing grazing the wall to flare burners each radiation chamber. Inside the reflector is divided into separate ducts whose number is twice the number of facets. Each duct is equipped with a rotary slide valve which serviced from a service platform.

At reflectors edges lying on two levels at the height of the faces are arranged rectangular channels for the supply of secondary air ducts to the flatness of the torch each face. By varying the air flow through the channels, you can adjust the degree of burn-in of grazing torch that aligns calorific adjustment pipe in the radiation chamber.

On the walls of the radiation chamber mounted single-row wall screens, and between the chambers of radiation - double-row radial screens bilateral irradiation.

If you change the heat output burners in the furnaces of the diagram summarizing the results of the heat flows virtually unchanged, but in each of the four chambers of radiation can maintain their calorific values mid-lowered pipe surface of the radiation chamber of the screen.

The combustion gases - through the chimney and the gas collector.

There are manufacturing furnaces in four sizes.

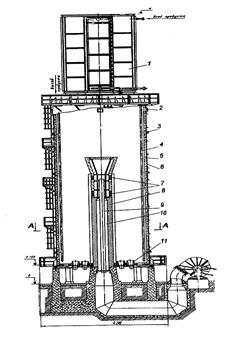

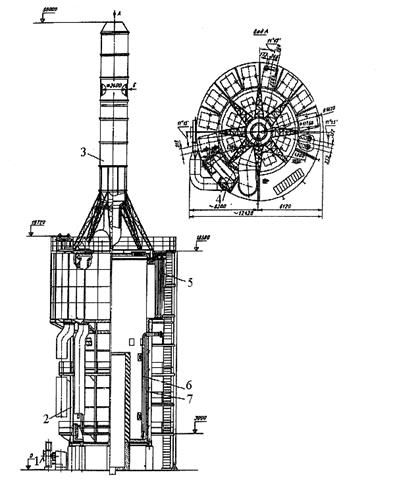

General view of the furnace and the foundation bolts plan of arrangement are shown in Figures 2.49.

1 – convection chamber; 2 and 3 – the exhaust, and a viewing window; 4 – radiant coil; 5 – lining; 6 – corpus; 7 – chamber for the supply of secondary air; 8 – lining reflector-spreader; 9 – air duct; 10 – spreader- reflector; 11 – burner

Figure 2.49 – Tubular furnace with four chambers of the central prism in the furnace with grazing torch and the differential supply air plume height, single-row and double-row wall intersection screen

d) The cylindrical tube with annular chamber furnaces convection cells in vertical tubes radiation and convection.

These furnaces - cylindrical with annular chamber convection, integrated air heater and a cooling coil in vertical cells to radiation and convection-free vertical flare combustion.

Combined burner type are located in the hearth.

On the walls of the radiation chamber set single-row or double-row tube wall screen. Convection coils as well as the air heater and dialed sections located in the annular chamber convection established according to the cylindrical radiant chamber.

Tap of the combustion gases - through the chimney and the gas collector.

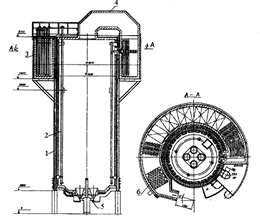

General view of the furnace shown in Figure 2.50.

1 – carcass; 2 – radiant coil; 3 – convective coil; 4 – lining; 5 – burner; 6 – air heater

Figure 2.50 – Tubular single-chambered cylindrical with the annular chamber of convection furnace, with vertical pipes in chambers of radiation and convection

Four-chambered furnace with central prism in the furnace, with grazing and the differential supply air plume height, single-row and double-row interchamber wall screens with a vertical pipe screens and convection arrangement, grazing combined fuel combustion.

Constructive performance of the furnace may be performed with a chimney, installed on the furnace or with standing separately chimney. Combined burner blower arranged in the furnace bottom. Burner axis tilted towards spreader-divider installed in the center of the furnace.

The splitter constructed in the form of a pyramid with concave faces, representing grazing the wall to flare burners each radiation chamber. The splitter has the following functions: divide the amount of radiant chamber into four self-contained heat exchange zone, which allows the differential supply of heat along the length of radiant coil; a floor surface torch burners, which are compared to the free stable thickness, which allows to bring the pipe screens burners and reduce the chamber volume.

The furnace is a two-stage fuel combustion. Primary air (70 % vol) is fed forcibly to the burners and the remainder - height deck, which in the masonry faces divider on two tiers adjustment faces arranged channels of rectangular cross section, and a frame divider - separate ducts whose number is twice the number of faces. Each duct is equipped with a rotary slide valve. Two-stage burning torches makes it possible to stretch the height of faces and increase the uniformity of the radiation adjustment radiant tubes.

On the walls of the radiation chamber mounted single-row wall screens, and between the chambers of radiation - double-row radial screens bilateral irradiation.

Convective coil, as well as air heater, typed sections and placed in the annular chamber convection, located under the cylindrical radiant chamber.

The combustion gases - through the chimney and the gas collector.

General view of the furnace shown in Figure 2.51.

1 – fan; 2 – carcass; 3 – chimney; 4 – convective coil; 5 – radiant coil; 6 – lining

Figure 2.51 – Tubular furnace with four chambers of the central prism in the furnace, with grazing torch and the differential supply air plume height, single-row and double-row wall interchamber screens